Meta Title: Micro Air Vacuum Pump: Complete 2025 Guide for Professionals and DIYers

Meta Description: Learn everything about micro air vacuum pumps — how they work, types, applications, specifications, maintenance, and the best models for 2025.

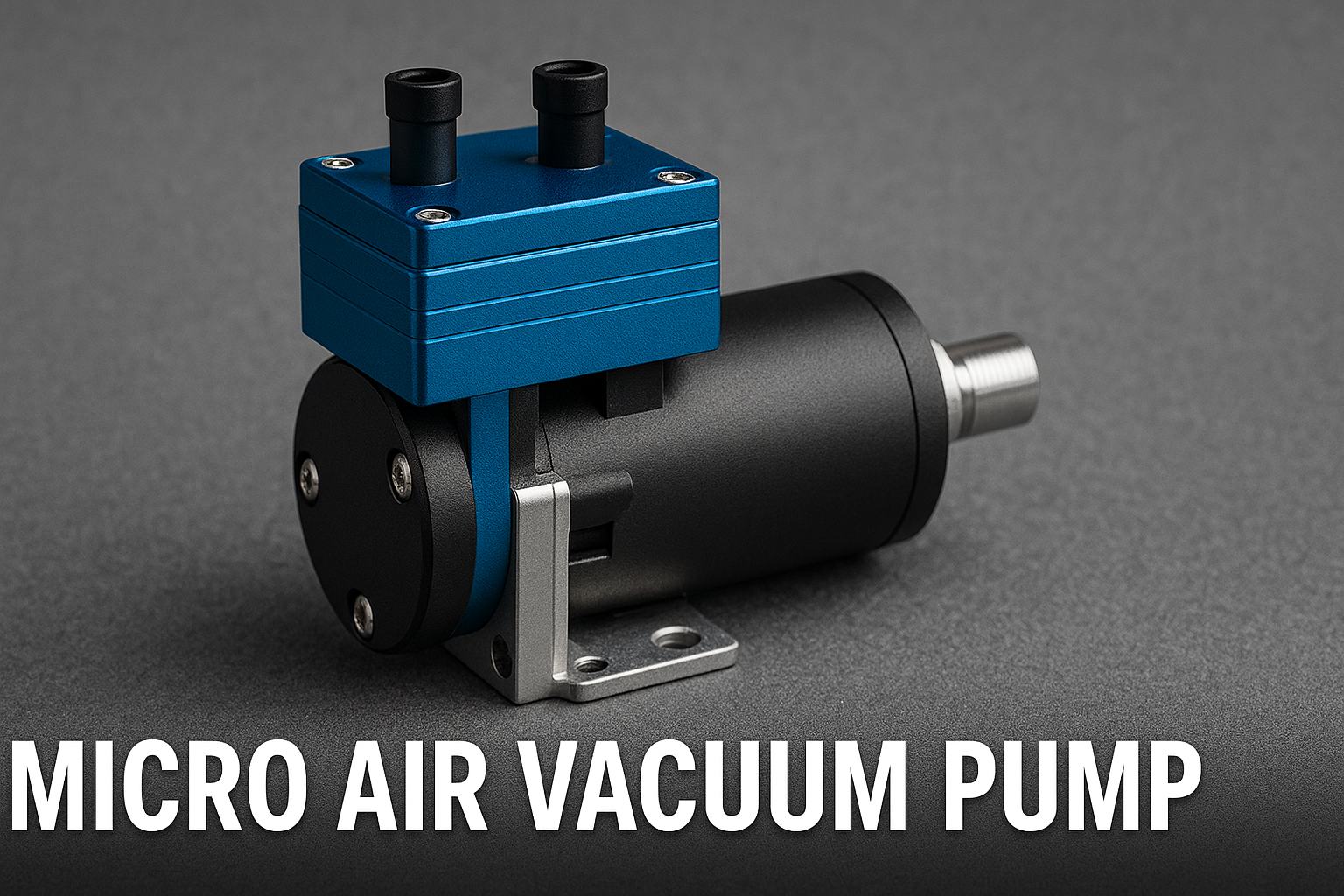

Introduction

If you work in medical devices, laboratory research, automation, or precision manufacturing, chances are you’ve come across a micro air vacuum pump—even if you didn’t realize it.

These compact, high-performance pumps can generate negative pressure (vacuum) or positive pressure (airflow) inside a small, lightweight housing. Despite their size, they’re capable of handling tasks that once required much larger equipment, making them a go-to solution for portable, efficient, and low-maintenance pneumatic systems.

This in-depth guide will help you understand what micro air vacuum pumps are, how they work, the different types available, their uses, buying considerations, maintenance tips, and top models—so you can choose the right one for your project or business.

What is a Micro Air Vacuum Pump?

A micro air vacuum pump is a miniature device that moves air or gas to create either suction or pressure. Unlike industrial-sized vacuum pumps, these are designed for space efficiency, low noise, and precise control rather than massive flow rates.

Most micro pumps are oil-free, meaning they run without lubrication, which:

- Reduces maintenance needs

- Prevents contamination

- Makes them suitable for medical and cleanroom environments

How Micro Air Vacuum Pumps Work

All vacuum pumps operate by removing air molecules from a sealed chamber, lowering the internal pressure below atmospheric levels. In micro pumps, this is achieved by mechanical movement that traps and pushes air out through an outlet port.

Depending on the design, this may involve:

- Changing chamber volume (as in diaphragm pumps)

- Rotating vanes to sweep air away (rotary vane pumps)

- Compressing air in a cylinder (piston pumps)

- Moving air through flexible tubing (peristaltic designs)

Some models are reversible, so they can switch between vacuum and pressure functions simply by changing motor rotation.

Main Types of Micro Air Vacuum Pumps

1. Diaphragm Pumps

- Mechanism: A flexible diaphragm moves up and down to create suction and discharge.

- Pros: Oil-free, low vibration, quiet, long lifespan.

- Cons: Lower maximum vacuum and flow rate compared to rotary designs.

- Best For: Medical devices, laboratory instruments, gas sampling.

2. Rotary Vane Pumps

- Mechanism: Sliding vanes in a rotating drum sweep air into a compression chamber.

- Pros: Can achieve deeper vacuum, smooth continuous operation.

- Cons: More moving parts, sometimes requires lubrication.

- Best For: Industrial automation, robotics, continuous suction applications.

3. Piston Pumps

- Mechanism: A piston moves inside a cylinder to compress and expel air.

- Pros: High pressure/vacuum capability, durable.

- Cons: Heavier, noisier, more mechanical wear.

- Best For: Applications needing high vacuum or high pressure.

4. Peristaltic Gas Pumps

- Mechanism: Rollers compress flexible tubing to push air or gas through.

- Pros: Air never touches internal parts, reducing contamination risk.

- Cons: Lower flow rate, bulkier relative to output.

- Best For: Contamination-sensitive environments, specialized lab work.

5. Brushless & Multi-Chamber Designs

- Brushless DC Motors: Longer lifespan, quieter operation, energy efficient.

- Multi-Chamber Pumps: Reduce pulsation for smoother airflow.

Applications of Micro Air Vacuum Pumps

1. Medical & Healthcare

- Ventilators, respirators, and CPAP machines

- Blood pressure monitors

- Dental suction tools

- Negative pressure wound therapy systems

- Gas sampling in diagnostic equipment

Why: Quiet, oil-free operation with precise control for patient safety.

2. Laboratory & Scientific Research

- Gas chromatography

- Air and gas sampling

- Vacuum filtration

- Microfluidics and lab-on-chip systems

Why: Compact design fits into benchtop and portable devices.

3. Industrial & Manufacturing

- Pick-and-place robotic arms

- Electronics assembly lines

- 3D printers and CNC machines

- Pneumatic control systems

Why: Reliable suction without large-scale vacuum infrastructure.

4. Consumer & Small Appliances

- Aquarium aeration

- Food vacuum sealers

- Coffee brewing systems

- Home fragrance diffusers

Why: Quiet operation and low energy use for home environments.

Key Specifications to Consider

- Vacuum Level

- Measured in kPa or mmHg

- Shallow vacuum: -20 to -50 kPa (medical use)

- Deep vacuum: -80 kPa or more (lab or industrial)

- Flow Rate

- Measured in L/min or mL/min

- Higher flow = faster evacuation

- Power Supply

- Common voltages: 3V, 6V, 12V, 24V DC

- Brushless DC motors last longer

- Noise Level

- Ideal for quiet environments: <50 dB

- Duty Cycle

- Percentage of continuous run time without overheating

- Size & Weight

- Critical for portable devices

- Materials

- Plastic for lightweight use

- Metal for industrial durability

How to Choose the Right Pump

| Application | Key Priority | Recommended Type |

|---|---|---|

| Portable medical device | Quiet, oil-free | Diaphragm |

| Gas analysis | Deep vacuum | Rotary vane |

| DIY electronics | Low power use | Brushless diaphragm |

| Robotics | Continuous suction | Rotary vane or piston |

Maintenance Tips

- Keep inlet filters clean

- Follow duty cycle limits

- Replace worn diaphragms or vanes promptly

- Use correct voltage and avoid overloading

- Store in dry, dust-free environments

Troubleshooting

| Problem | Cause | Fix |

|---|---|---|

| Weak suction | Worn parts or leaks | Replace seals, check tubing |

| Loud noise | Loose mounts or worn bearings | Tighten, replace bearings |

| Overheating | Exceeded duty cycle | Allow cool-down periods |

| No start | Electrical fault | Check wiring and power supply |

Future Trends

- IoT-enabled micro pumps with real-time monitoring

- Bio-inspired designs for ultra-low power use

- MEMS integration for microscopic applications

- Advanced brushless motors for longer service life

Top Recommended Models

- Thomas 107CDC20 – Compact, oil-free diaphragm pump

- KNF NMP 850 KN – High precision for analytical devices

- DC 370 Micro Pump – Budget-friendly, versatile

- Bodenflo BZ Series – Brushless, PWM control, durable

FAQs

Q: Can these pumps run continuously?

A: Only if rated for continuous duty—otherwise follow rest cycles.

Q: Are they suitable for liquids?

A: Standard models are for gases—use liquid-compatible designs for fluids.

Q: How deep a vacuum can they achieve?

A: Most reach -50 to -90 kPa, depending on type.

Conclusion

A micro air vacuum pump may be small, but it can deliver a huge impact in precision, portability, and performance. By understanding the different types, applications, and technical specifications, you can confidently choose a model that matches your needs—whether it’s for a medical device, lab instrument, or industrial machine.

With proper selection and maintenance, these pumps can run for thousands of hours, providing reliable suction or airflow wherever you need it.