1. Introduction

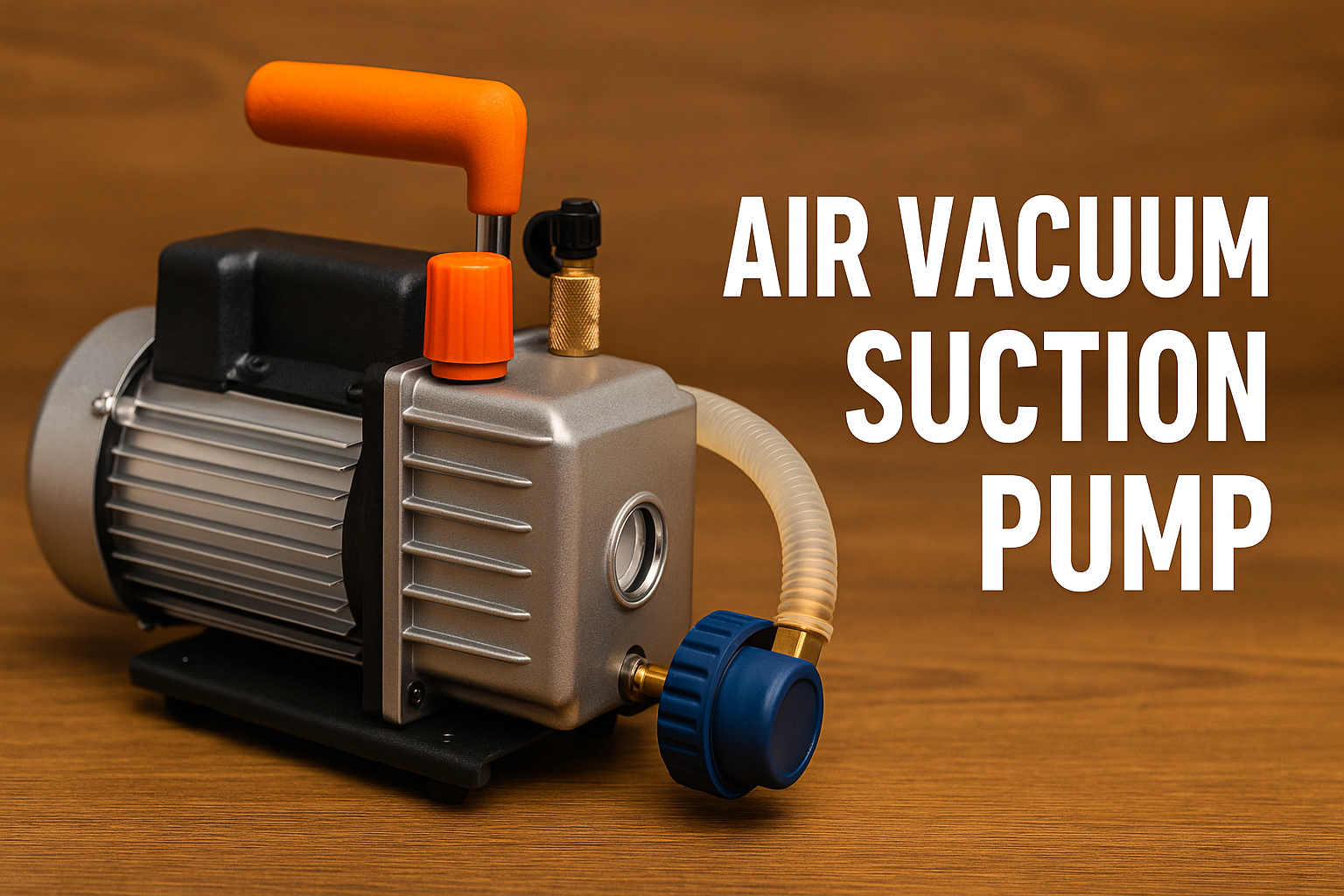

In the world of industrial tools and machinery, few devices are as versatile and widely used as the air vacuum suction pump. Whether it’s holding a delicate electronic component during assembly, evacuating refrigerant from an HVAC system, or creating the perfect vacuum seal in packaging, this tool is essential for precision and efficiency.

Unlike conventional household vacuums, these pumps are engineered for specialized technical and industrial environments, where controlled suction and vacuum generation are critical to the process. Their reliability and adaptability have made them a standard in fields like automotive repair, laboratory testing, manufacturing automation, packaging, and even aerospace engineering.

In this in-depth guide, you’ll learn:

- What an air vacuum suction pump is

- How it works (with technical but clear explanations)

- Different types and their strengths

- Real-world applications across multiple industries

- Performance specifications you must know before buying

- Expert tips for selection, operation, and maintenance

- Future innovations shaping the industry

2. What Is an Air Vacuum Suction Pump?

An air vacuum suction pump is a mechanical device that removes air (or other gases) from an enclosed space to create a vacuum, enabling suction-based handling or pressure control. By lowering the air pressure inside a chamber below atmospheric levels, the pump causes external air or liquids to flow in, following the principle of pressure differential.

Key Characteristics:

- Power Source: Can be powered by compressed air (pneumatic) or electricity.

- Output: Creates suction for handling materials or vacuum for process control.

- Versatility: Works with gases, and in certain designs, with fluids (when liquid handling features are integrated).

- Compact or Industrial Size: Available from small, handheld models to large-scale industrial units.

3. How It Works: Step-by-Step Process

Air vacuum suction pumps operate based on fluid mechanics and thermodynamics. Let’s break it down:

- Initiation – The pump is connected to a power source (either compressed air line or electric motor).

- Air Movement – Internal components (rotary vanes, pistons, or Venturi jets) displace or carry away air from the target chamber.

- Pressure Reduction – As air is evacuated, the internal pressure drops below atmospheric pressure.

- Suction Creation – The pressure difference between the chamber and the outside environment causes surrounding air or fluid to flow in.

- Continuous Operation – Depending on design, the pump can maintain a steady vacuum or cycle as needed.

Science Note:

The core principle follows Pascal’s Law and Bernoulli’s Principle—utilizing pressure changes to generate movement of fluids (including air).

4. Types of Air Vacuum Suction Pumps

Understanding pump types is essential for selecting the right one for your task. Below are the main categories:

4.1 Rotary Vane Vacuum Pumps

- How They Work: Contain rotor blades inside a housing that rotate to trap and expel air.

- Advantages: Reliable, good for medium-to-high vacuum levels, handles continuous operation.

- Common Uses: Refrigeration evacuation, lab experiments, medical suction devices.

4.2 Air-Operated (Pneumatic) Vacuum Pumps

- How They Work: Use compressed air to generate suction through a Venturi effect.

- Advantages: Lightweight, no electrical components, safe in explosive environments.

- Common Uses: On-site automotive repairs, HVAC servicing, material handling in factories.

4.3 Venturi Vacuum Pumps (Ejector Pumps)

- How They Work: High-speed compressed air passes through a narrowing nozzle, creating a vacuum.

- Advantages: No moving parts, maintenance-free, compact.

- Common Uses: Robotic pick-and-place, packaging lines, small-scale lab setups.

4.4 Piston Vacuum Pumps

- How They Work: A reciprocating piston draws air in and pushes it out, lowering chamber pressure.

- Advantages: Very high vacuum capability, robust design.

- Common Uses: Industrial degassing, vacuum forming, heavy-duty suction applications.

4.5 Scroll Vacuum Pumps

- How They Work: Two spiral-shaped scrolls trap and compress air, pushing it out gradually.

- Advantages: Quiet, oil-free, efficient.

- Common Uses: Cleanroom applications, semiconductor manufacturing, medical equipment.

5. Applications Across Industries

Air vacuum suction pumps are used everywhere—here are just a few sectors where they’re indispensable:

5.1 Manufacturing

- Holding components in CNC machines

- Removing air bubbles from adhesives and resins

- Dust removal during production

5.2 Automotive

- Brake bleeding

- Air conditioning system evacuation

- Fluid transfer systems

5.3 Packaging

- Vacuum sealing food products

- Removing oxygen to extend shelf life

- Bottle and jar filling without air pockets

5.4 Laboratories

- Filtration and distillation processes

- Gas sampling

- Contamination-free fluid transfers

5.5 Electronics

- PCB handling with suction cups

- Component placement in automation lines

6. Important Specifications to Consider

When choosing a pump, evaluate:

| Specification | Why It Matters |

|---|---|

| Vacuum Level | Determines how strong the suction is (measured in Torr, Pa, or inHg). |

| Flow Rate | Affects how quickly the pump can evacuate a space (liters/min or CFM). |

| Noise Level | Crucial for labs, medical, or quiet workspaces. |

| Power Source | Compressed air vs. electric; impacts portability and cost. |

| Materials | Stainless steel, aluminum, or composite plastics for chemical resistance. |

| Size & Weight | Important for handheld or mobile applications. |

7. Choosing the Right Air Vacuum Suction Pump

Follow this checklist:

- Identify your application (e.g., packaging, automotive, lab).

- Determine required vacuum strength.

- Check available power source (air compressor, electricity).

- Consider maintenance—some types need oiling, others are oil-free.

- Evaluate budget vs. lifespan—quality pumps last years with proper care.

8. Maintenance Tips for Longevity

- Clean intake filters regularly to avoid clogging.

- Check seals and gaskets for wear to prevent leaks.

- Lubricate moving parts where applicable.

- Run pump under load periodically to prevent stagnation.

- Store in a dry, dust-free environment when not in use.

9. Advantages & Limitations

Advantages:

- Compact and portable models available

- No direct electrical hazard for pneumatic versions

- High versatility across industries

Limitations:

- Pneumatic models require a compressed air source

- Some high-vacuum pumps require regular oil changes

- Noise can be an issue in certain designs

10. Future Trends in Air Vacuum Suction Pumps

- IoT Integration – Real-time monitoring and predictive maintenance alerts.

- Energy Efficiency – Improved Venturi designs that use less compressed air.

- Noise Reduction – Advanced mufflers and vibration-dampening housings.

- Material Innovation – Lightweight composites for portable models.

11. FAQ

Q1: Can I use an air vacuum suction pump for liquids?

A: Only if it’s designed for wet applications—standard models are for gases.

Q2: What’s the difference between vacuum pressure and suction?

A: Suction is the action; vacuum pressure is the measurable difference from atmospheric pressure.

Q3: Do Venturi pumps need electricity?

A: No, they run solely on compressed air.

12. Conclusion

The air vacuum suction pump remains a critical tool in both small workshops and large-scale industries. From robotics to refrigeration, its applications are broad, its technology refined, and its potential for future innovation vast.

If you understand how it works, the different types available, and which specifications matter most, you can select a pump that will serve you reliably for years—saving costs, improving efficiency, and enhancing the quality of your work.